Tour

Located in the rural town of Hawk Point Missouri, the 10 acre Tim McAmis Performance Parts campus features four facilities sprung over 30,000 square feet that allow it’s companies to design, engineer, manufacture and distribute state-of-the-art drag racing components.

FAB SHOP

Where it all started...

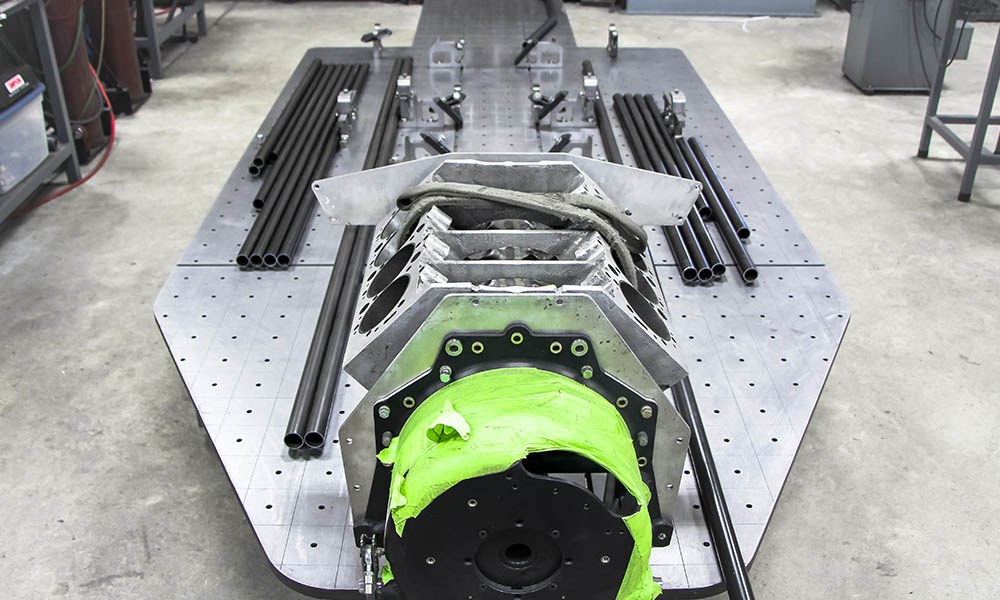

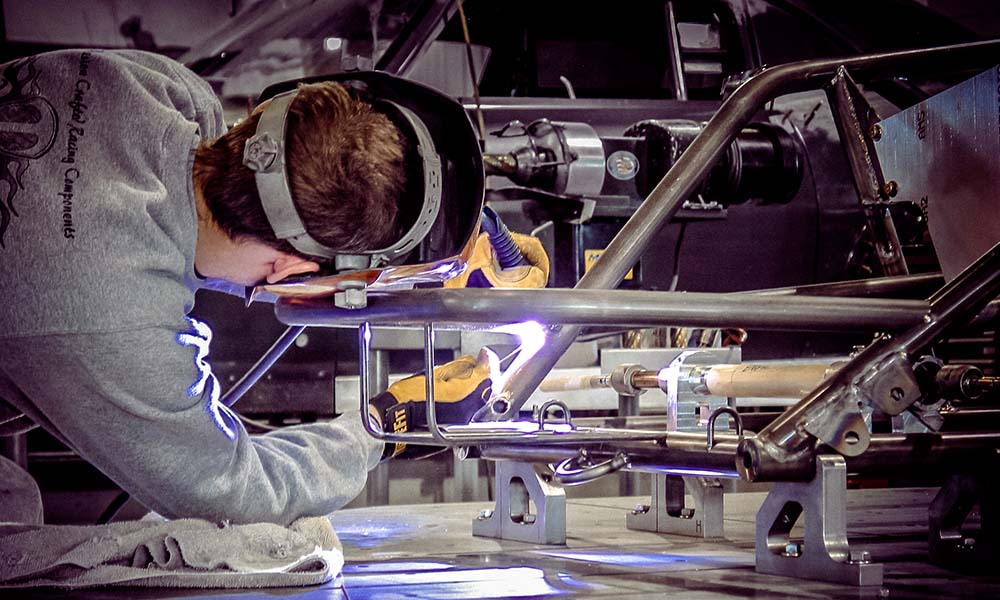

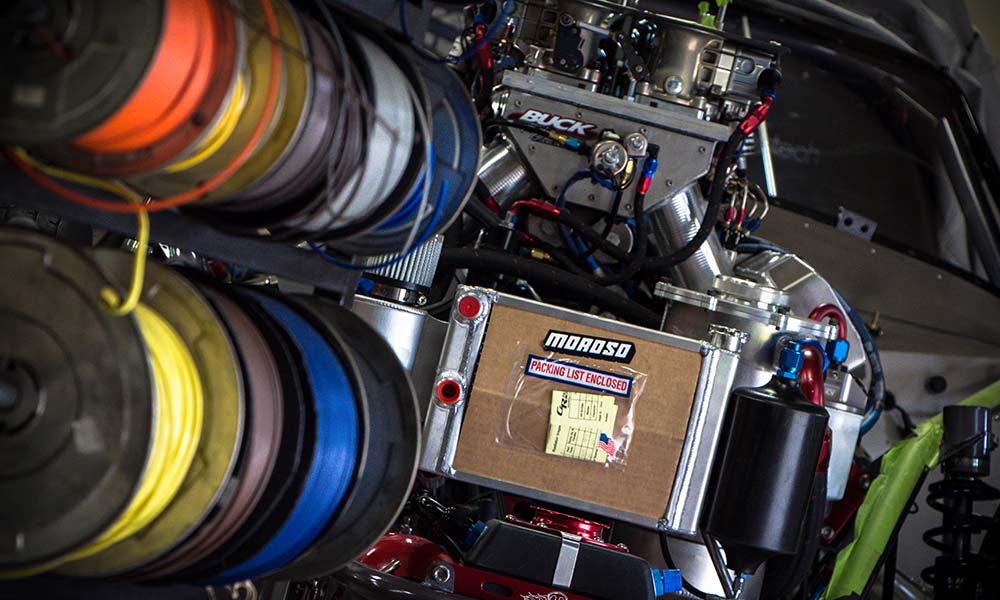

The fabrication shop houses the Tim McAmis Race Cars division of the TMPP companies. Over the years the fabrication shop has seen many changes while keeping with the times, but its soul remains intact. DNA from many of the world’s quickest, fastest, championship-winning doorslammers through the past 25 years has ingrained itself into these walls.

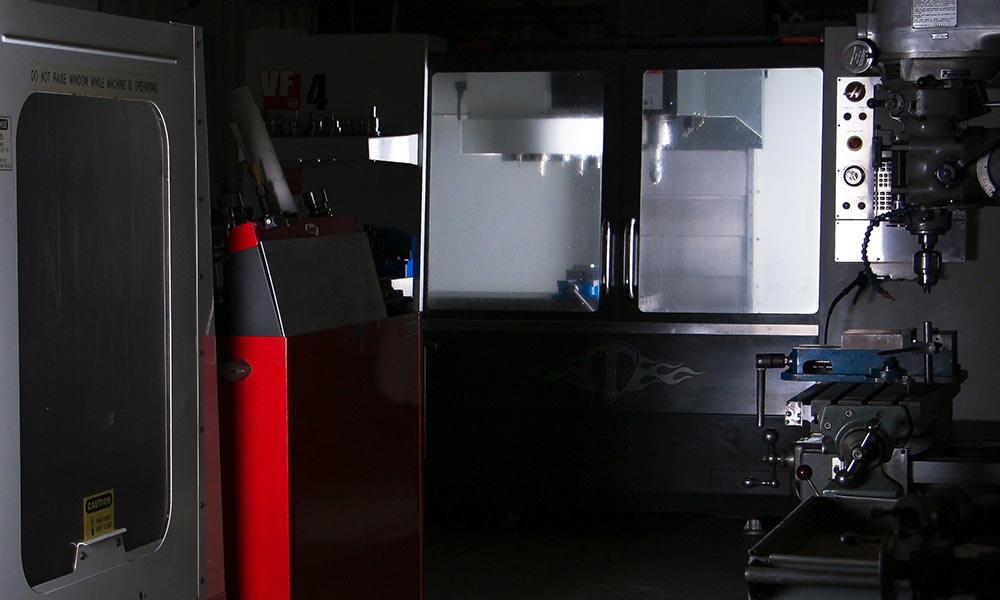

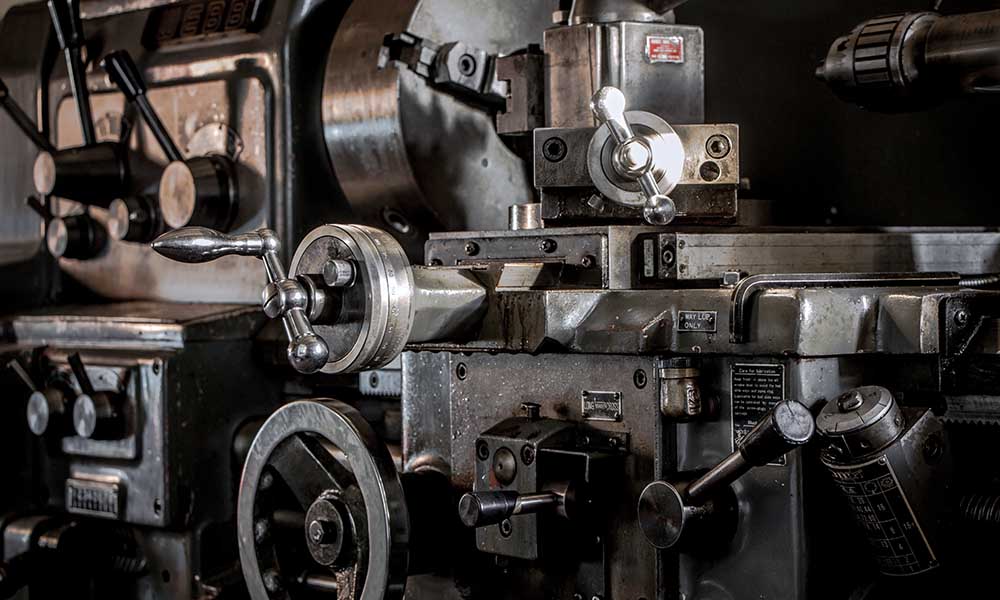

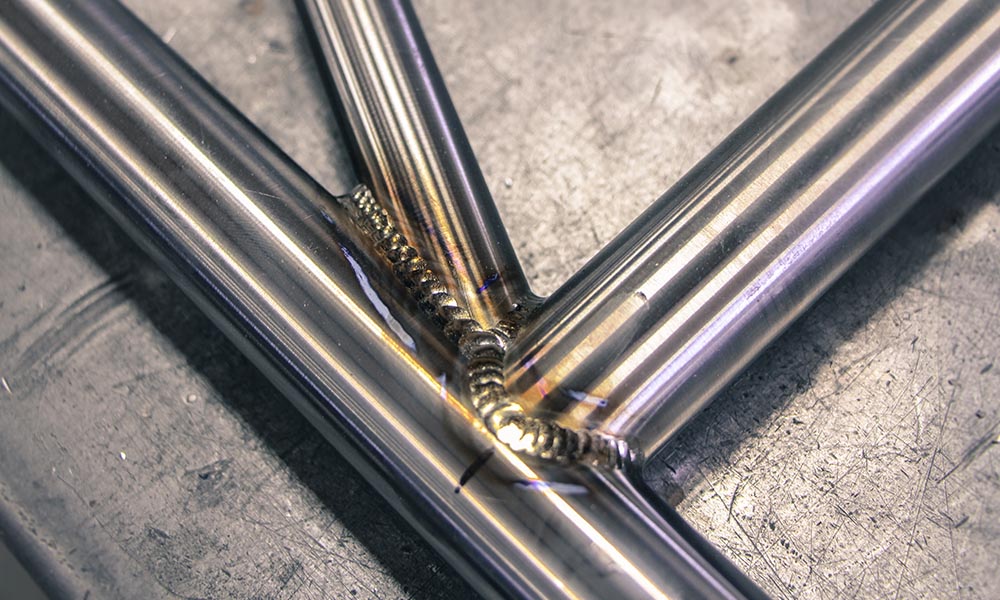

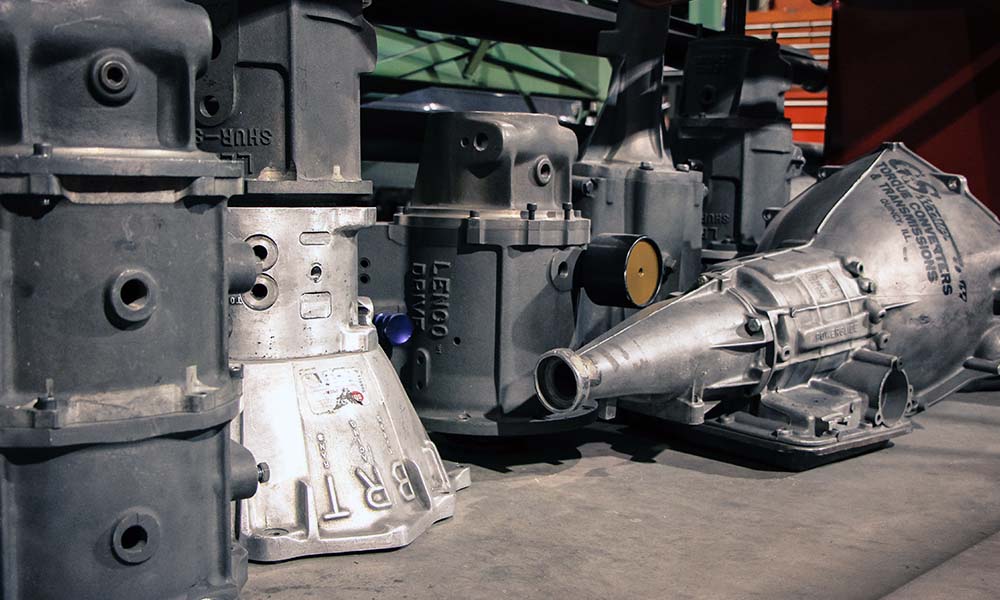

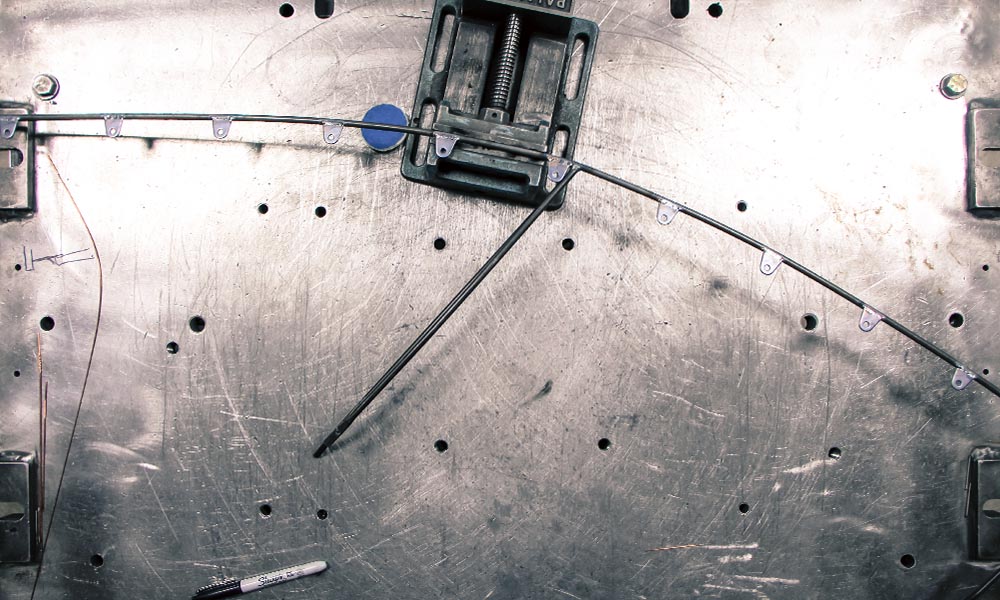

Today, the facility features a wide range of the latest equipment from HAAS CNC machines to tubing benders, notchers, lathes, brakes, welders and its revolutionary chassis tables and jigs.

Everything within the fabrication shop is centered around accuracy and efficiency. Years of development has produced hundreds of industry-specific tools and fixtures that allow our expert craftsmen to produce stunningly consistent stock and custom products.

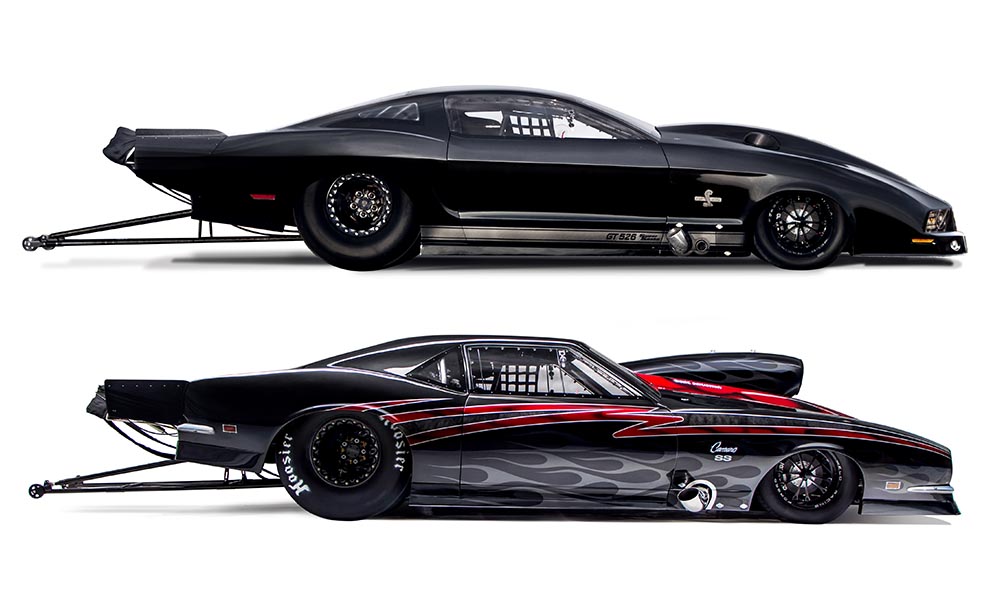

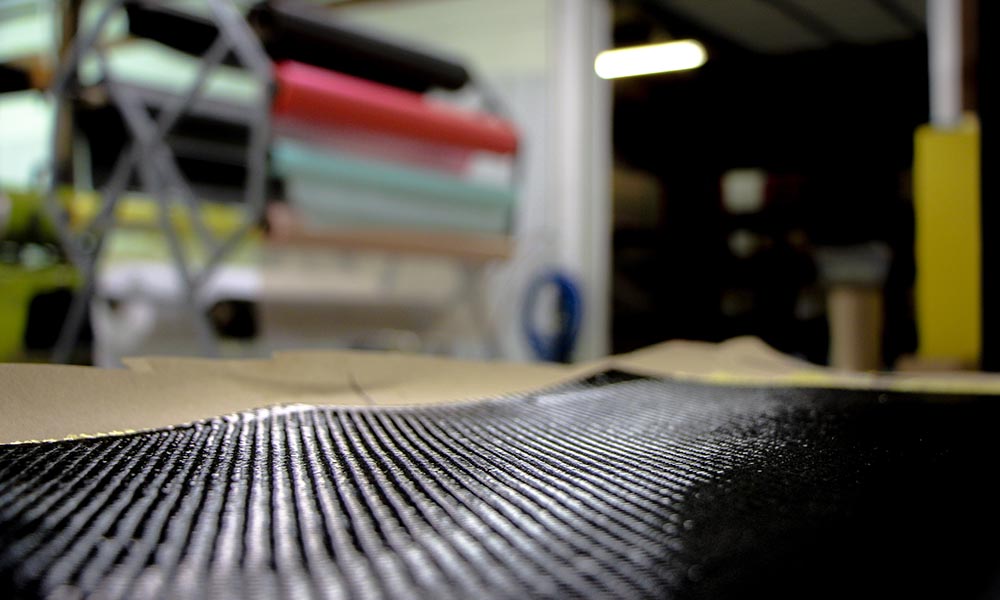

The composite manufacturing facility at TMPP was formed in the late 1990’s out of necessity. As a race car builder, McAmis found it increasingly difficult to find professional level composite pieces such as seats and hood scoops. The limited number of items that were available were severely lacking in their construction and consistency.

After perfecting the ability to produce smaller items with an unmatched quality, the composite shop began developing new products such as the first carbon fiber wheel tubs and tube protectors. Eventually the decision to create a full composite body was made the team started with a ’57 Chevy.

Today, the composite facility known as Velocity Composites has gained a reputation for supplying the industry’s highest quality products that contain an exceedingly sought after structural integrity as well as a show-stopping finish.

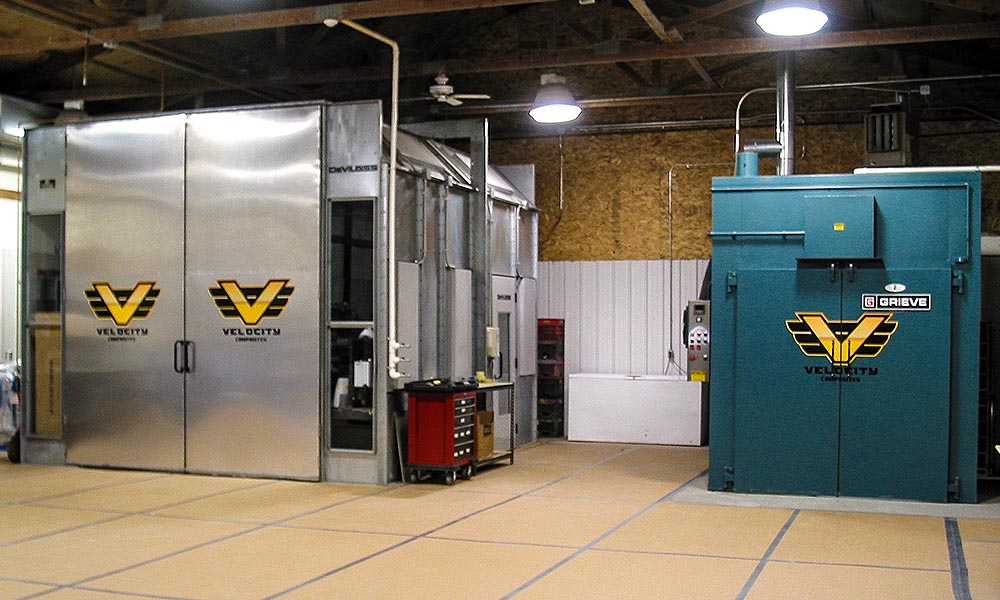

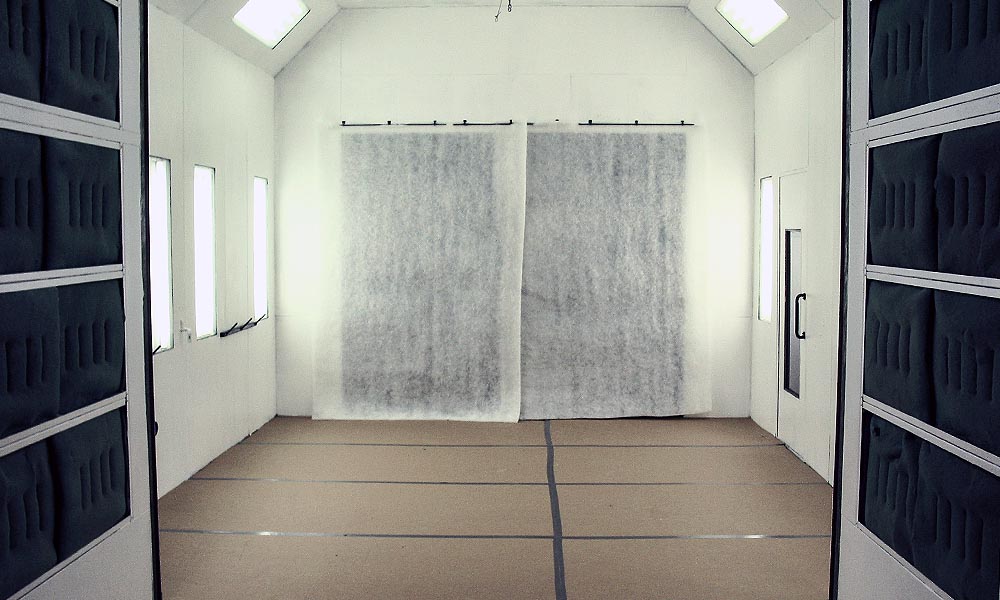

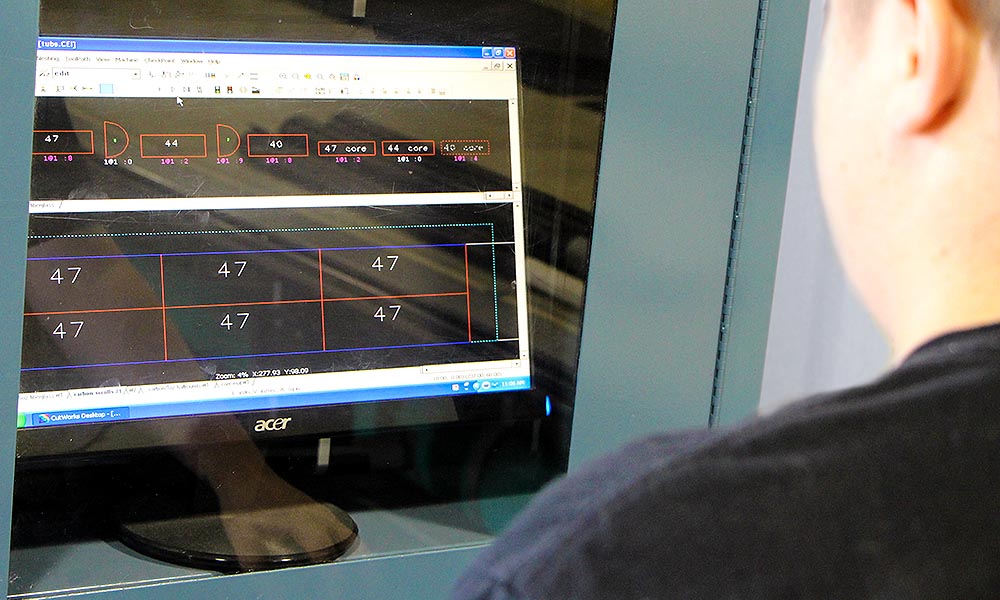

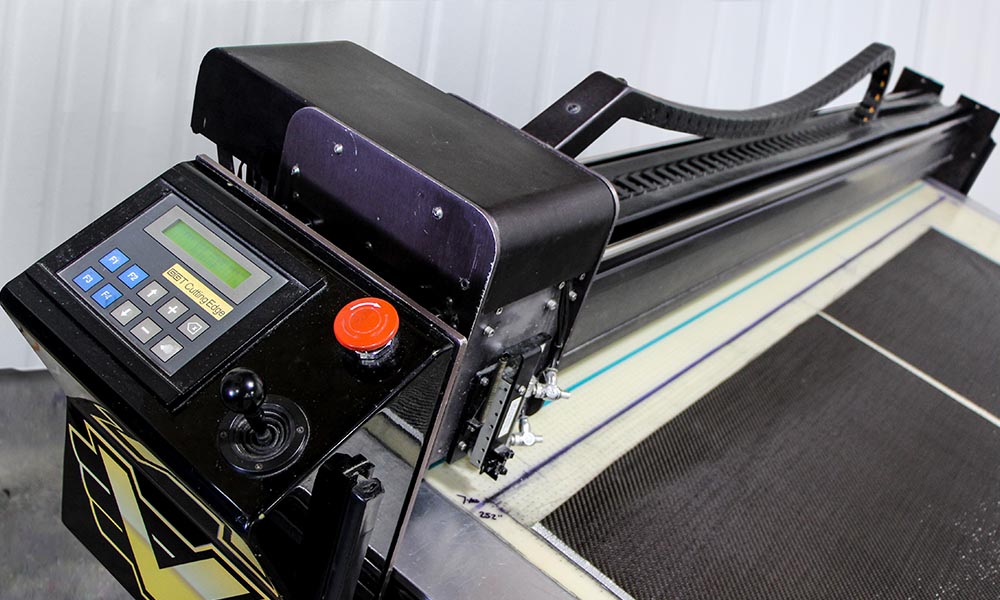

The facility allowed Velocity to introduce processes and equipment never before seen in drag racing such as vacuum bagging and computer controlled cutting tables. Inside Velocity, you will find equipment such as a 24’ CNC cutting table, 500 degree controlled curing oven, DeVilbiss spray booth, spray machines, vacuum machines, compressors along with fabrication equipment for producing molds and plugs.

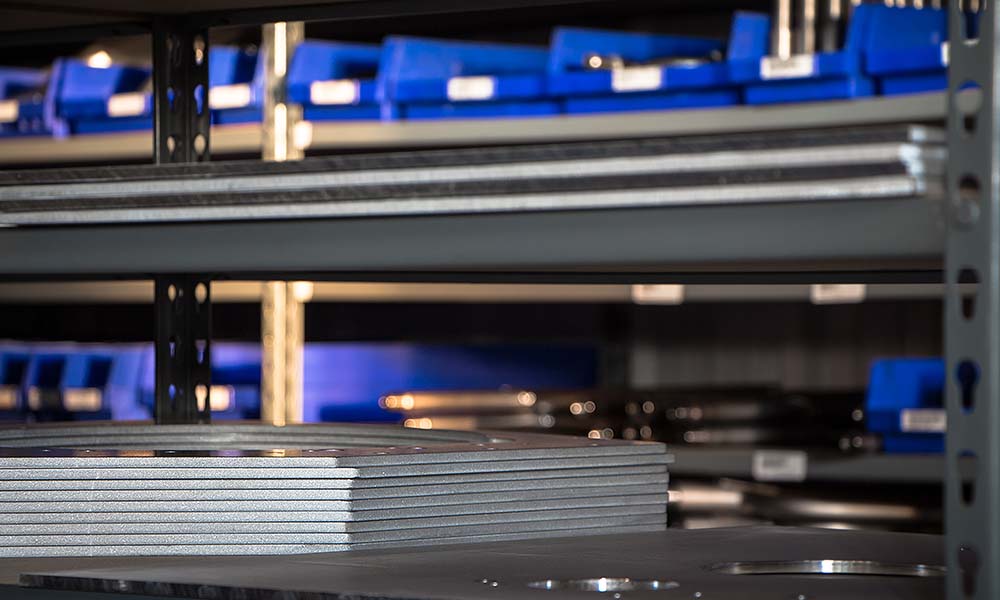

Within the TMPP warehouse products from over 50 brands, including those manufactured by TMRC and Velocity, are stocked and organized using an advanced inventory and tracking system.

The moment an order is placed, our fulfilment and sales teams are notified of items purchased and their locations to properly assemble and transfer to the shipping department.

Located within the warehouse, the shipping department utilizes industrial packing equipment such as labelers, formers, bag sealers, stretch wrappers and end of line packing tools.

After individual orders are assembled, orders are hand packed with care and attention to detail. You will never find a lack of bubble wrap in your box or a need for more heavy duty tie down straps on a shipping pallet.

Watch us fill a shipping container for All-In Race Cars of Denmark...